Kazan Model Dynamics

KMDKLG4801EDU 1:48 Kazan Model Dynamics HybridCAST Landing Gear Set - Bf 109G-5 and Later (EDU kit)

- SKU:

- KMDKLG4801EDU

- MPN:

- KLG4801EDU

- Scale:

- 1/48

Frequently bought together:

Description

For the Eduard kits

Kazan Model Dynamics proudly introduces an innovative new approach to an aspect of modelling aircraft that often falls well short of the standard of a finished build, and addresses several annoying shortcomings of what is currently available and possible. The manufacturing process culminates in landing gear legs and retraction struts with exposed metal oleos and pistons that look incredibly realistic, have no mould seams, and only require masking. Even the masking is not entirely necessary, as a gentle scraping of any paint applied will remove it without scuffing the metal.

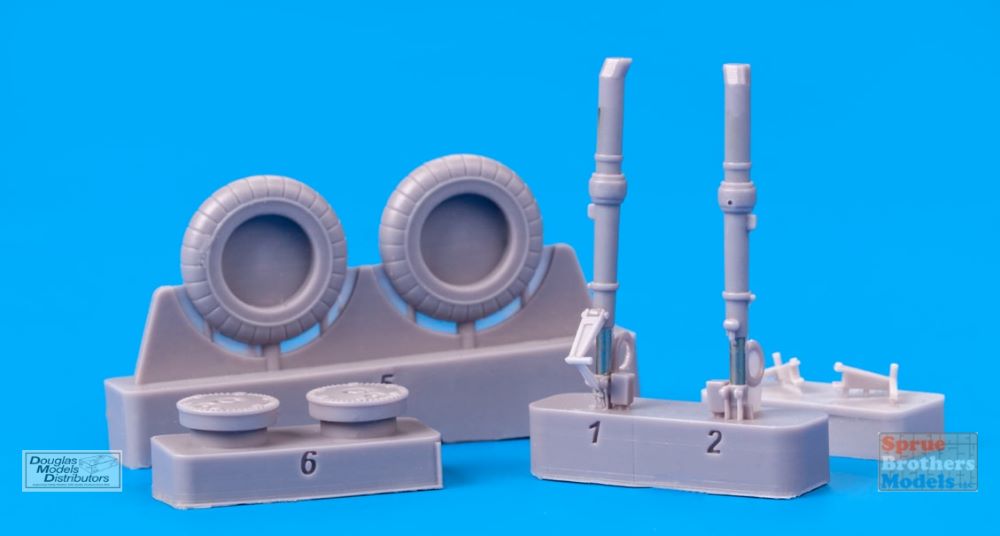

What you see here is the collection of eight components making up the set. In the second photo, the main leg, Part No.1, has the torque links attached, but they are not glued in place. The initial concept, which has been preserved as an integral part of the product's success, required making sure that a buildable product was being sold, and part of this was deemed to be some form of deflection of those that like to use the term 'fiddly' in connection with modelling. The line between 'fiddly' and 'fidelity of detail' is clouded and overlapping, but is often used, and always used in a derogatory way. Our approach to addressing this was to make, wherever possible, any attachment of parts, especially the smaller ones, a 'friction' fit, if not an outright snap fit. This allows for very clean and tidy gluing, as well as greatly easing the process, reaping unsurpassed detail as the main benefit. The parts are still small, but that is a function of scale, and we take no responsibility for that.

The metal forms the main bearing material, and the resin picks up the rest. The gear was load tested over extended periods of time to 300% finished model weight to ensure that the resin (love that stuff!) resisted creep where bending moments were generated. To top it off, the tests involved resin only prototypes (with no metal) and at 300% weight, the legs themselves bent, but no movement whatsoever was registered where, intuitively, the bending moment should have manifested itself. Of course, the metal that reinforces the gear and replicates the oleo piston prevents the bending that was observed in the tests. The metal extends the length of the leg, but not into the casting block, meaning no metal needs to be cut when assembling and prepping the gear. That would be mean.